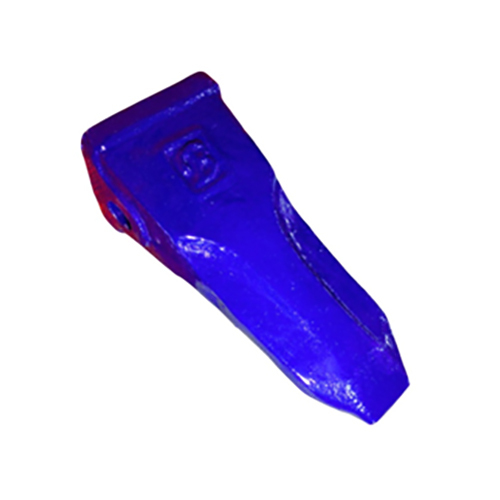

TATA 400 RC Bucket Tooth Points

TATA 400 RC Bucket Tooth Points Specification

- Product Type

- Tooth Points

- General Use

- Earth moving machinery parts

- Material

- Other

- Type

- Bucket Tooth Points

- Moving Type

- Crawler Excavator

- Computerized

- No

- Automatic

- No

- Hydraulic Steering

- No

- Control System

- Manual

- Feature

- Environmental Friendly

- Color

- Black

- Warranty

- 1 Year

TATA 400 RC Bucket Tooth Points Trade Information

- Minimum Order Quantity

- 25 Pieces

- Supply Ability

- 1000 Pieces Per Month

- Delivery Time

- 7 Days

- Main Domestic Market

- All India

About TATA 400 RC Bucket Tooth Points

TATA 400 RC Bucket Tooth Points areheavy-duty excavation components, made from high-strength, heat-treated alloy steel for superior impact and abrasion resistance.They feature a smooth contour design to maximize digging penetration and fatigue resistance, providing high system strength and a lower cost-to-life ratio for earthmoving machinery like excavators and loaders.These points are designed for durability, rugged construction, and extended operational life in demanding.Premium Quality Earth-Moving Components

Our TATA 400 RC Bucket Tooth Points ensure superior strength and wear resistance, making them the preferred choice for demanding excavator tasks. Crafted for crawler excavators, these parts provide reliable earth penetration with a manual operation system, supporting precise control in challenging terrains.

Environmental Sustainability and Durability

Designed to minimize ecological impact, these bucket tooth points are made using environmentally friendly processes and materials. Their robust build and 1-year warranty ensure long-lasting service life and reduced replacements, helping operators work more efficiently and sustainably.

FAQs of TATA 400 RC Bucket Tooth Points:

Q: How are TATA 400 RC Bucket Tooth Points installed on a crawler excavator?

A: Installation is a manual process that typically involves securing the bucket tooth points to the excavator bucket with bolts or pins. The procedure requires basic mechanical tools, and no computerized or automatic systems are needed.Q: What is the main use of TATA 400 RC Bucket Tooth Points in earth-moving machinery?

A: These tooth points are designed for ground penetration, digging, and breaking up tough soil. They are attached to excavator buckets to enhance digging efficiency and durability during earth-moving tasks.Q: Where can I procure TATA 400 RC Bucket Tooth Points, and are they exported outside India?

A: You can obtain these bucket tooth points from authorized exporters, manufacturers, and suppliers in India. International export is available, making them accessible in various countries.Q: When should I consider replacing my excavators bucket tooth points with the TATA 400 RC model?

A: Replacement is recommended when existing teeth show significant wear, reduced digging performance, or visible damage. Upgrading to TATA 400 RC Tooth Points can restore optimal operation and extend equipment longevity.Q: What benefits do TATA 400 RC Bucket Tooth Points offer over other brands?

A: Their environmentally friendly manufacturing, robust design, and reliable performance stand out. The included 1-year warranty assures quality and durability, and their suitability for manual control systems adds versatility.Q: Does the product require hydraulic or computerized control for its operation?

A: No, the TATA 400 RC Bucket Tooth Points operate manually and do not require any hydraulic steering or computerized control, making them compatible with basic crawler excavator setups.

Price 400.0 INR/ Piece

- Minimum Order Quantity

- 25 Pieces

- Supply Ability

- 1000 Pieces Per Month

- Delivery Time

- 7 Days

- Main Domestic Market

- All India

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Excavator Bucket Tooth Points Category

TATA 210 RC Bucket Tooth Points

Price 400 INR / Piece

Minimum Order Quantity : 25 Pieces

Feature : Environmental Friendly

Warranty : 1 Year

Color : Black

Product Type : Bucket Tooth Points

TATA EX 70 Bucket Tooth Points

Minimum Order Quantity : 25 Pieces

Feature : Environmental Friendly

Warranty : 1 Year

Color : Black

Product Type : Tooth Points

VOLVO 290 RC Tooth Points

Price 400 INR / Piece

Minimum Order Quantity : 25 Pieces

Feature : Environmental Friendly

Warranty : 1 Year

Color : Black

Product Type : Tooth Points

TATA EX 200 Bucket Tooth Points

Minimum Order Quantity : 25 Pieces

Feature : Environmental Friendly

Warranty : 1 Year

Color : Blue

Product Type : Tooth Points

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free